If you are deciding how to assemble a printed circuit board, the choice often comes down to two proven methods: Through-Hole PCB Assembly and Surface Mount Technology.

If you are deciding how to assemble a printed circuit board, the choice often comes down to two proven methods: Through-Hole PCB Assembly and Surface Mount Technology.

Understanding the difference between Through-Hole PCB Assembly and SMT will help you balance strength, size, speed, and cost.

DSL Electronic Manufacture supports both approaches in the UK, so you can use one process or combine them within a single build for the best outcome. In this blog post we explore both methods in more detail, the differences and when you might use one over the other.

What is Through-Hole PCB Assembly?

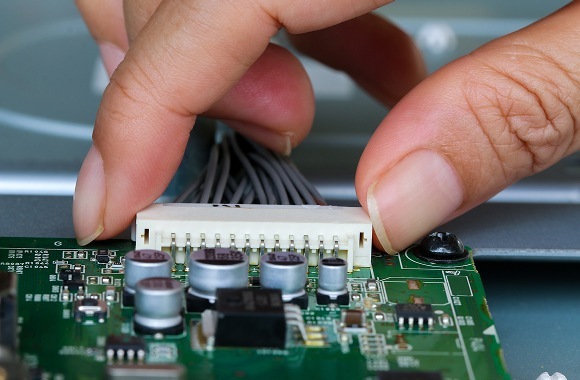

Through-hole assembly places component leads into drilled holes on the PCB and solders them on the opposite side. This creates a secure mechanical joint that stands up well to stress, vibration, and high power loads. It is a popular choice for heavier parts such as transformers, large electrolytic capacitors, connectors, and switches, and for applications where durability is critical.

What is Surface Mount Technology (SMT)?

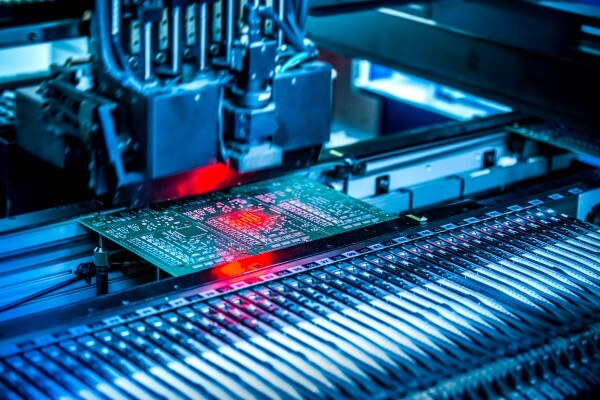

SMT mounts components directly onto pads on the surface of the PCB. In production, solder paste is printed on the pads, components are placed with automated pick and place systems, and connections are formed during reflow soldering. The method supports high component density, fast runs, and efficient, repeatable quality at volume.

The key differences at a glance

- Mounting style

- Through-Hole: leads through drilled holes, soldered on the reverse.

- SMT: terminations land on surface pads.

- Mechanical strength

- Through-Hole: stronger physical anchoring for stressed parts.

- SMT: adequate for most devices that do not experience mechanical strain.

- Speed and scalability

- Through-Hole: more manual work, slower for very high volumes.

- SMT: highly automated, ideal for compact and complex designs.

- Typical use cases

- Through-Hole: power electronics, connectors, rugged environments.

- SMT: miniaturised consumer, telecoms, and high-density industrial designs.

When to combine the two

Most real products mix both techniques. High pin‑count ICs, passives, and modules usually sit on the SMT line, while mechanically stressed parts such as heavy inductors or panel connectors are anchored with through-hole. This hybrid approach gives you compact layouts without compromising on robustness.

DSL’s Assembly Capability

Through-Hole Capability

DSL offers manual, wave, and selective soldering for through-hole assembly. Selective soldering is particularly useful on mixed-technology PCBs because it applies solder precisely where needed without disturbing nearby SMT parts. Each assembly goes through appropriate preparation, trimming, inspection, and testing to confirm mechanical and electrical integrity.

DSL’s SMT Capability

DSL’s SMT process covers paste printing, automated pick and place, and controlled reflow. Setup includes loading design data, aligning stencils, and calibrating feeders and vision systems for accurate placement. The automated line supports consistent, high-quality output from prototypes through to production.

Why teams choose DSL Electronic Manufacture

- Mixed-technology builds under one roof in the UK

- Proven methods for rugged through-hole parts plus high‑efficiency SMT

- 5‑year manufacturing warranty that covers defects in workmanship

- Free NRE to remove upfront barriers when you launch or redesign

FAQ’s: The difference between Through-Hole PCB Assembly and SMT

What is the main difference between Through-Hole PCB Assembly and SMT?

Through-hole PCB Assembly inserts component leads into drilled holes for a strong mechanical joint. SMT places components on surface pads and forms joints during reflow.)

Which option is more reliable?

Reliability depends on context. Through-hole offers superior mechanical strength for stressed or heavy parts. SMT is highly reliable for the vast majority of components when designed and manufactured correctly.

Which is more cost effective?

For high volumes and dense layouts, SMT is usually more economical due to automation and smaller components. Through-hole can be more labour intensive but is essential where mechanical strength is needed.

Can I use both on one PCB?

Yes. Many designs combine SMT for ICs and passives with through-hole for connectors, power devices, or other stressed parts. Selective soldering helps integrate both without affecting nearby SMT joints.

When should I choose Through-Hole PCB Assembly over SMT?

Choose through-hole for applications with vibration, frequent mating and unmating of connectors, high currents, or physically large components that benefit from through‑board anchoring.

When should I choose SMT?

Select SMT for compact products, high component counts, faster assembly cycles, and consistent quality at scale.

How does DSL handle inspection and testing?

Assemblies go through appropriate inspection and testing steps to verify electrical and mechanical integrity. On the SMT line this is supported by automated processes and controlled reflow.

Does DSL really offer Free NRE and a 5‑year warranty?

Yes. DSL highlights Free NRE for PCB assembly projects and an industry‑leading 5‑year manufacturing warranty that covers defects.

If you are weighing the difference between Through-Hole PCB Assembly and SMT for your next project, send DSL your design goals, expected volumes, and environmental constraints. The team will recommend an approach or a mixed build that protects the right components with through-hole while keeping the rest fast, compact, and cost efficient on the SMT line.