SMT Assembly (Surface Mount Technology)

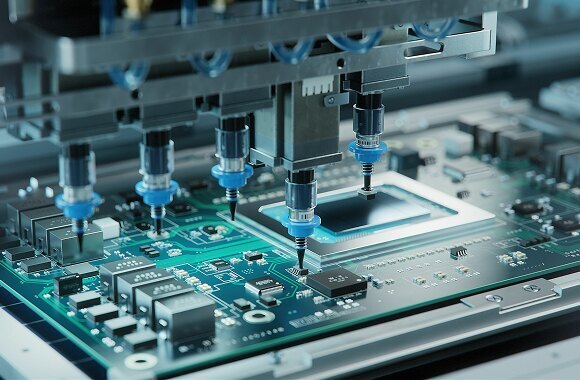

SMT (Surface Mount Technology) assembly is a highly efficient and precise process that ensures the accurate placement of electronic components onto a printed circuit board (PCB). At DSL Electronic Manufacture, we handle SMT assembly in two key phases: setup and running. Each phase varies in duration depending on the complexity of the PCB design and the quantity being produced, ensuring optimal efficiency and accuracy.

SMT Assembly Setup Phase

Before production begins, all SMT machinery, from the solder paste applicator to the Pick and Place machine, is loaded with the design files. This ensures that every component is placed accurately according to the PCB layout, minimising errors and optimising production efficiency.

Once the design files are loaded, the next step is physically preparing the components. Each component must be loaded onto reels, trays, or feeders, depending on its size and type. This process requires careful attention, as incorrect placement or misalignment can lead to defects later in assembly. Placement heights and centres are meticulously configured and validated using advanced measurement tools to ensure each part is positioned with the highest accuracy.

The solder paste stencil must be aligned with the PCB to ensure precise deposition of solder paste onto the designated pads. The setup phase also includes calibrating the pick-and-place machine’s vacuum nozzles and vision system, which are responsible for correctly identifying and positioning components during assembly. These detailed steps are crucial in guaranteeing a smooth transition into the running phase of SMT assembly.

Why Clients Choose DSL

DSL’s exceptional client feedback stems from our commitment to quality, innovation, and tailored customer service. Our team’s expertise and dedication ensure reliable electronic manufacturing solutions that meet specific client needs. We prioritise effective communication and support, fostering lasting relationships by delivering consistently high-quality and timely products.

Quality and Innovation

Customised Solutions

Reliable Communication

Customised Solutions

Contact us today

Speak to one of our knowledgeable and experienced team.

SMT Assembly Running Phase

- Solder Paste Application – The PCB moves through a solder paste applicator, which deposits solder paste onto thousands of tiny pads with extreme precision, ensuring no excess material is applied.

- Pick and Place – The PCB is transferred via conveyors to the Pick and Place machine. Here, each component is individually picked up by a vacuum arm, photographed for orientation verification, and placed onto the PCB with micron-level accuracy.

- Reflow Soldering – The now populated PCB is moved through a multi-phase reflow oven, where precise temperature control melts the solder paste, securing the components in place.

Why SMT Assembly Matters

SMT assembly is crucial for achieving high-speed, high-precision electronic manufacturing. The automation involved ensures consistency, accuracy, and efficiency in placing surface-mount components. By optimising the setup and running phases, DSL Electronic Manufacture delivers high-quality PCBs with minimal errors, reducing production time and costs.

Partner with DSL for Expert SMT Assembly

With advanced SMT equipment and a team of experienced professionals, DSL Electronic Manufacture ensures that every PCB assembly meets the highest industry standards. Our expertise in setup and precision placement guarantees reliable, high-performance electronic products.

Get in touch with DSL Electronic Manufacture today to discuss your SMT assembly requirements. Whether for prototypes or full-scale production, we provide precision, efficiency, and quality you can trust.