Short answer, no. PCB assembly is the process of turning a bare printed circuit board into a populated electronic assembly, while an embedded system is a complete, purpose‑built computer that combines hardware and software to perform a specific function. The two are tightly linked. Every embedded system needs a physical platform, and that platform is almost always a PCB assembly that has been designed and built to meet strict electrical, thermal and mechanical constraints.

Short answer, no. PCB assembly is the process of turning a bare printed circuit board into a populated electronic assembly, while an embedded system is a complete, purpose‑built computer that combines hardware and software to perform a specific function. The two are tightly linked. Every embedded system needs a physical platform, and that platform is almost always a PCB assembly that has been designed and built to meet strict electrical, thermal and mechanical constraints.

In this guide I will separate the terminology, then show how a production‑ready PCB assembly underpins embedded performance, reliability and certification. I will also reference real projects and explain why many UK OEMs trust DSL Electronic Manufacture for design‑for‑manufacture support, Free NRE, a five year warranty as standard and flexible delivery schedules that help cash flow.

What PCB assembly actually is

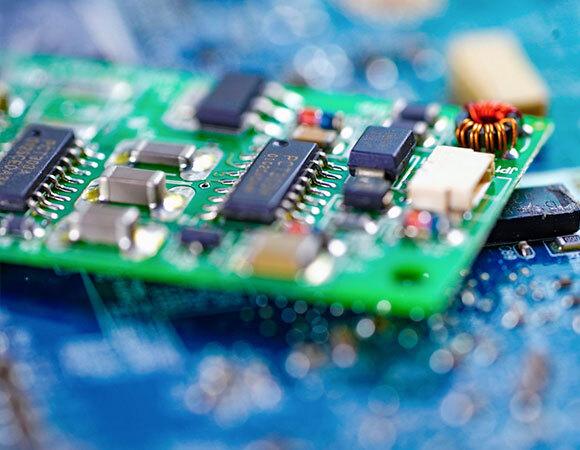

PCB assembly, often shortened to PCBA, is the act of placing and soldering components onto a bare PCB. In modern production lines this is achieved with surface mount technology for speed and precision, then finished with selective through‑hole soldering where mechanical strength or high voltage creepage is needed.

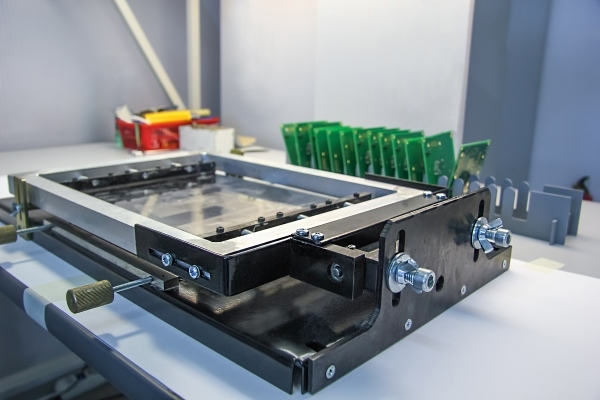

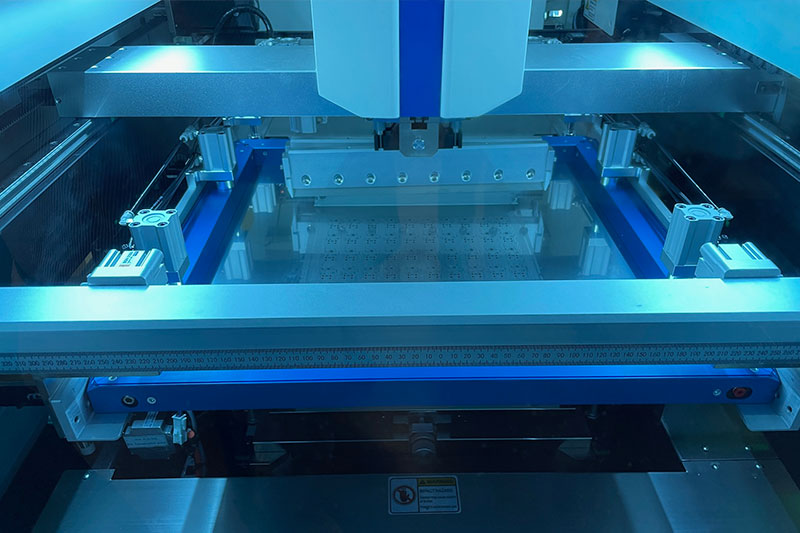

Quality is assured using automated optical inspection, followed by connectivity and functional testing to suit the product. DSL’s production flow reflects this best practice, combining stencil printing, dual in‑line pick and place machines, a multi‑zone reflow oven, 3D AOI, skilled hand insertion for THT and tailored functional test.

When you outsource assembly you are buying repeatable process control. That includes correct solder paste volumes, component placement within sub‑millimetre tolerances, controlled thermal profiles during reflow and complete, traceable inspection. DSL invests in a fully automated SMT line and 3D AOI on every build to deliver consistent quality for UK OEMs.

What an embedded system is

An embedded system is a specific combination of hardware and firmware that carries out a defined task inside a larger product. It might be a motor controller, a metrology instrument, a HMI panel or a safety logger. The embedded platform is the populated PCB. The firmware interacts with on‑board processors, memory, sensors and interfaces such as RS485, CAN, Ethernet, USB or wireless radios. Taken together, the PCBA and its firmware, plus any enclosure and cabling, form the embedded system.

This distinction matters. If you only assemble a PCB you do not yet have an embedded system in a strict sense. You need programming, calibration, functional test and usually a box build step to finish the product. DSL provides that one‑stop path from assembly through to box build and delivery, which is why many customers choose to keep the full chain under a single UK roof.

How PCB assembly enables embedded systems

Although the terms describe different things, the assembly stage sets up the conditions for embedded success. Here are the touch points that matter.

Design for manufacturability and test

A board that looks fine on paper can still be hard to build or verify. Early DFM and DFT checks catch footprint errors, missing test points, poor pad geometry, silk conflicts and thermal relief issues before you pay for a failed prototype. DSL offers a complimentary Design Health Check by in‑house engineers, so you can correct issues before first build and improve yield and reliability.

Programming and provisioning

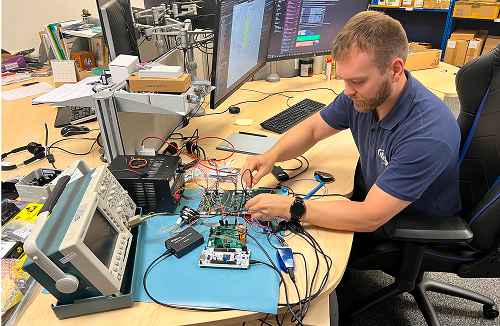

Most embedded assemblies need firmware loading, key injection, MAC address or serial number programming and sometimes secure boot configuration. Planning these steps around the assembly line reduces handling and mistakes. It is common to combine boundary‑scan or bed‑of‑nails programming with power‑on functional test to prove that CPU, memory, sensors and I/O are alive.

PCB Inspection and functional test

AOI confirms component presence, polarity and solder integrity. Functional test proves behaviour. For industrial devices that must run for years, this is the stage that weeds out infant mortality and verifies analogue accuracy, digital timing and interface integrity. DSL runs 3D AOI and then connectivity and functional tests tailored to the specification before any board leaves the line.

From bare board to box build

An embedded system is rarely just a board. It needs an enclosure, cabling, labels, licensing, and often burn‑in. DSL’s box build service can complete that stack, including firmware installation and serialisation, so you receive goods that are ready for the next stage of your integration or direct shipment.

Constraints that embedded projects place on assembly

Embedded systems live in the real world. That means a PCBA for embedded use must be built with these constraints in mind.

Power integrity and signal integrity

Noise on supplies or poor return path control can ruin ADC performance or destabilise radios. Assembly precision affects impedance targets and component parasitics. Correct solder volumes, reflow profiles and controlled handling of fine‑pitch parts are part of the solution.

Thermal and mechanical robustness

Thermal cycling and vibration are common in plant rooms, vehicles and outdoor cabinets. Through‑hole retention is often specified for connectors, transformers and high mass parts. Mixed SMT and THT processes must be sequenced to protect joints and prevent latent defects. DSL combines automated SMT with skilled through‑hole soldering to achieve the right balance of speed and mechanical strength

Compliance and lifetime expectations

Industrial buyers expect products to pass EMC and safety, then operate for years. That expectation should flow all the way back to the assembly line. ISO 9001:2015 process control, documented work instructions, AOI coverage and stable suppliers are the bedrock. DSL’s assembly service is ISO 9001:2015 certified and built around consistent processes that support compliance and long‑term reliability.

Serviceability and obsolescence

Over a decade or more, components will go end of life. Being able to re‑spin and re‑qualify assemblies with minimal disruption is part of the embedded lifecycle. Working with a CEM that also offers redesign support keeps you moving when supply chain shocks hit. DSL’s redesign capability and in‑house engineers help with drop‑in alternates and circuit tweaks when parts disappear.

A typical production path for an embedded product

- Requirements and architecture defined by your design team, often with input from the manufacturing partner on DFM and DFT. DSL’s engineers can collaborate at this stage and offer a free Design Health Check to derisk the first build.

- NPI and prototypes assembled on an automated SMT line, then finished with THT where needed, inspected by 3D AOI and functionally tested.

- EVT, DVT and PVT iterations refine layout, test coverage and firmware; yield data drives improvements.

- Serial production with flexible call‑offs that reduce warehouse burden and match your dispatch rhythm. DSL’s flexible delivery lets you benefit from the economy of a larger production run while only paying when you take a batch.

- Optional box build, labelling, licensing and final test so goods are ready to ship.

PCB Assembly case study insight

In industrial automation and instrumentation, the line between a complex PCBA and the embedded system it enables is especially clear. One published example describes work on Taylor Hobson’s Form Talysurf Intra precision measurement instrument. The goal was to condense functionality that previously spanned several PC add‑in cards into a compact, portable device, with embedded processor selection, multi‑protocol I/O and custom firmware.

That project combined high density surface mount layout, diverse interface integration and real‑time software, illustrating how a manufacturing partner that also understands embedded design can deliver a reliable instrument in a smaller footprint.

This is a useful lens for the original question. The PCBA itself is not the embedded system. It is the engineered platform that, once programmed, calibrated, boxed and tested, becomes the embedded instrument.

Why UK OEMs choose a UK manufacturing partner for embedded products

Local collaboration saves time and avoids translation issues, especially when requirements evolve and quick engineering discussions are needed. A UK partner simplifies visits, audits, prototypes and compliance conversations. DSL sets out the advantages of keeping assembly in the UK, including faster lead times, better communication, an industry leading five year warranty and Free NRE that removes setup costs that many manufacturers still charge as standard.

For time‑critical programmes, offshore shipping delays and customs risk hurt schedules. UK manufacture with flexible delivery reduces both delay and inventory carrying cost, while improving responsiveness when demand shifts.

Why work with DSL when your end goal is an embedded system

Even if your team brings the product architecture and firmware, the right CEM partner can make or break schedule, yield and customer satisfaction. Here is how DSL aligns with embedded projects.

- Free NRE, so you are not penalised for setting up the line, building stencils, programming pick and place or reflow profiles and designing test fixtures. Removing that barrier supports more thorough prototyping and iteration.

- Five year warranty as standard on assembly work, a strong signal that the process, materials and workmanship can support long service life in demanding environments.

- ISO 9001:2015 certified processes, with 3D AOI on every build, for repeatable quality and traceability that supports compliance and approvals.)

- UK facility in Letchworth with on‑site design engineers who solve manufacturability and reliability issues quickly and feed improvements back into your design.

- Flexible delivery schedules that allow you to call off stock in the quantities you need, reducing warehouse space and smoothing cash flow.

- End‑to‑end services beyond population, including redesign support when components go obsolete and full box build with firmware install, serialisation and functional test.

- Transparent communication and practical engineering input rather than a pure build‑to‑print relationship.

So, is PCB assembly an embedded system

No. PCB assembly is the manufacturing step that creates the hardware foundation for an embedded system. Your embedded system only comes to life when that assembly is programmed, tested and integrated into a mechanical envelope with the right firmware and accessories. Treat the assembly stage as the bridge between design intent and field performance. Choose a manufacturing partner that understands both sides of that bridge and you will ship robust products sooner.

FAQs

Is a PCBA the same thing as an embedded system

No. A PCBA is the populated board. An embedded system includes the board, firmware and any supporting mechanics or cabling that make it function inside a product.

What file outputs do I need to supply for assembly

Typically Gerbers or IPC‑2581, centroid data, a validated BOM, assembly drawings and any test plans. If you need a second set of eyes before build, DSL offers a complimentary Design Health Check to catch issues early.)

Do I need both SMT and through‑hole

Most modern designs are SMT‑first for speed and density. Through‑hole is still used where stronger mechanical retention or creepage is required, for example on connectors and high mass parts. DSL sequences SMT and THT for precision and robustness.

How is quality controlled on the line

Stencil printers ensure correct paste volumes, pick and place machines deliver accurate positioning, a controlled reflow oven sets joint integrity and 3D AOI checks every board against a golden reference. Functional test then proves behaviour

Can you programme firmware and label units during build

Yes. Programming, serialisation and licensing are common steps during production, often combined with functional test, then completed at box build so units are ready to ship.

What does Free NRE cover

The setup work that other CEMs usually charge for, such as stencil manufacture, machine programming and test setup. DSL’s Free NRE removes that upfront cost, which helps first builds and second‑source transfers.

What warranty should I expect

Many providers offer twelve months. DSL backs assembly work with a five year warranty as standard, reflecting confidence in process and workmanship

Do you support flexible call‑offs

Yes. You can build economically at scale and call off stock in batches to match demand, which improves cash flow and reduces warehouse burden.

Do you handle redesign if parts go end of life

Yes. DSL’s in‑house engineers can recommend alternates or modify circuits to keep production flowing.

Can you manage the whole embedded product build

Yes. From SMT and THT assembly to test, programming, labels, cabling and final enclosure, DSL provides box build so products leave ready for integration or shipment.

PCB assembly and embedded systems are not the same, but they are inseparable in practice. If you are designing an embedded product, involving your manufacturing partner early gives you cleaner handovers, fewer surprises and better first‑time yield. If you want to keep prototyping agile and risk low, DSL’s Free NRE, five year warranty, ISO 9001:2015 quality and flexible call‑offs are a strong foundation for your programme, with on‑site engineers who understand both design and production.

If you would like a friendly sanity check on your files or a discussion about yield, test coverage or delivery cadence, get in touch with the DSL team.